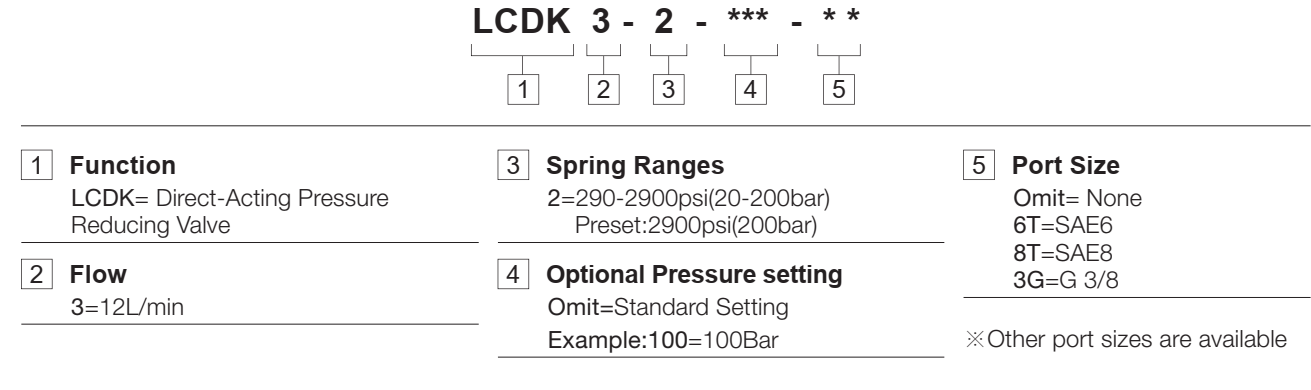

- Reducing Valves

- Relief Valves Reducing Valves Sequence Valves Pilot Unloading Valves

Up all

Pack up all

-

Technical Feature

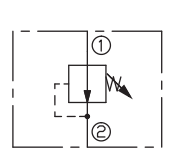

OPERATION:

In its steady state, the valve allows flow from ① to ② . The spring chamber is vented to atmosphere.On attainment of a pre-determined pressure at ② ,the cartridge shifts to restrict input flow at ① ,thereby regulating pressure at ② .

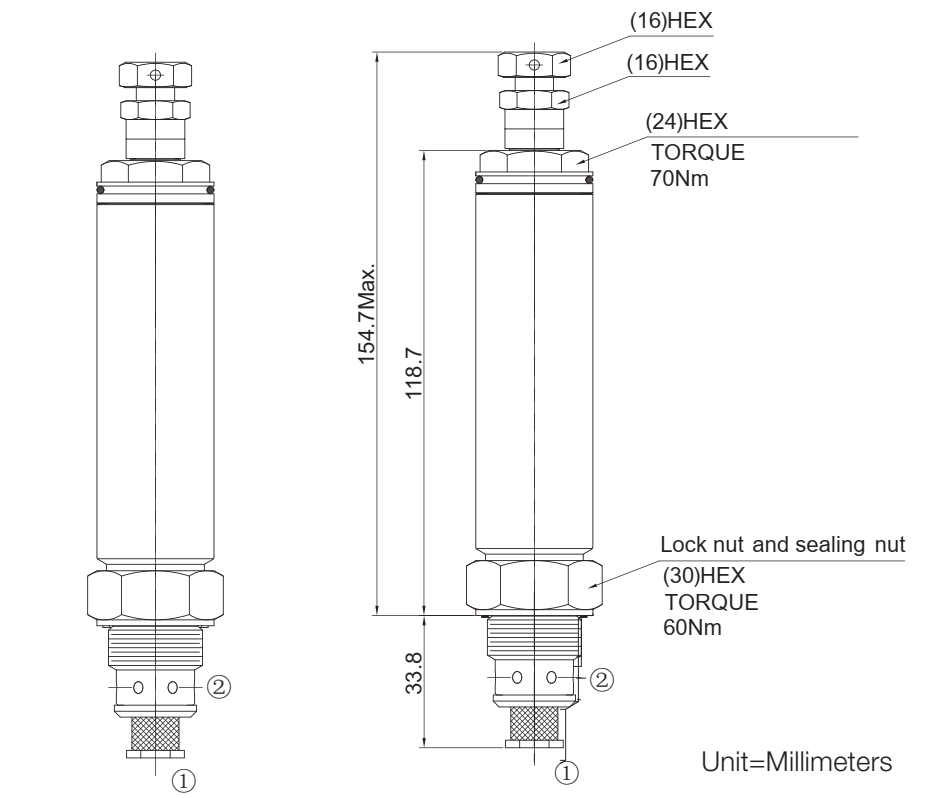

ASSEMBLY INFORMATION:

1. Before screwing in the valve, loosen the lock nut and sealing nut until the travel stop.

2. Screw in the valve and tighten with the specified torque. The metallic sealing of the inlet to the outlet is formed between the facial sealing edge of the valve and the shoulder of the stepped hole in the basic body.

3. Tighten lock nut and sealing nut with specified torque. -

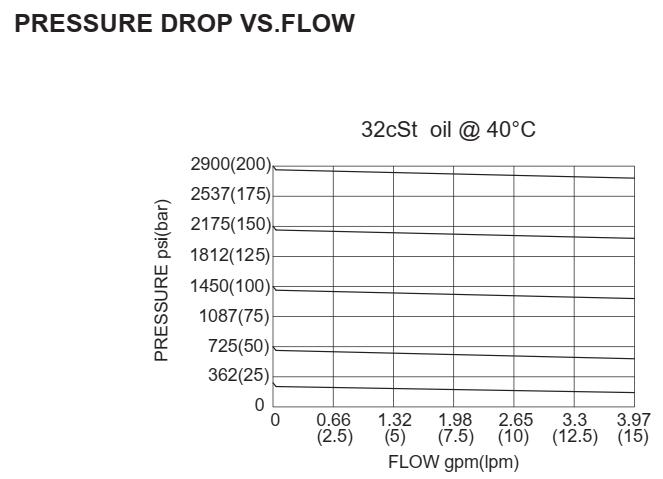

PerformanceCurves

-

Technical Data

Operating Pressure500barFlowSee PRESSURE DROP VS.FLOW graph.CavityCDK3FiltrationRefer to "Cleanliness of Hydraulic Fluid"Internal Leakage<1 drops/min. in closed stateReseat Pressure80% of crack pressure(crack pressure at 0.95lpm/0.25gpm)Standard Spring Ranges15 to 130 bar; preset:130bar

20 to 200 bar; preset:200bar

30 to 300 bar; preset:300barTemperature-40ºF to +250ºF(-40ºC to +120ºC)FluidsMineral-based fluids with viscosities of 7.4 to 420 cSt.Body MaterialSteel & Ductile iron rated to 350bar -

File Download

PDF File -

ACCESSORIES